Keller’s ability to assemble experienced personnel and resources in-house to perform all techniques under one turnkey contract streamlined the overall ground improvement/foundation installation operation.

The project

PacifiCorp intended to establish 66,1.5-MW, 260-ft high turbines on a 300-acre portion of 14,000 acres of land reclaimed from discontinued surface coal mining operations.

The challenge

Construction on reclaimed mine land typically presents some unique challenges. Due to varying coal seam depths in the open surface pits, the resulting backfill material (spoil/overburden) thickness and composition can vary significantly throughout the mine area. Following a detailed geotechnical investigation, specific locations at Rolling Hills were identified by the owner’s engineer as requiring either ground improvement by deep dynamic compaction (DDC), or deep foundations in the form of micropiles or driven piles, to safely support the proposed turbines’ mat foundation slabs.

The solution

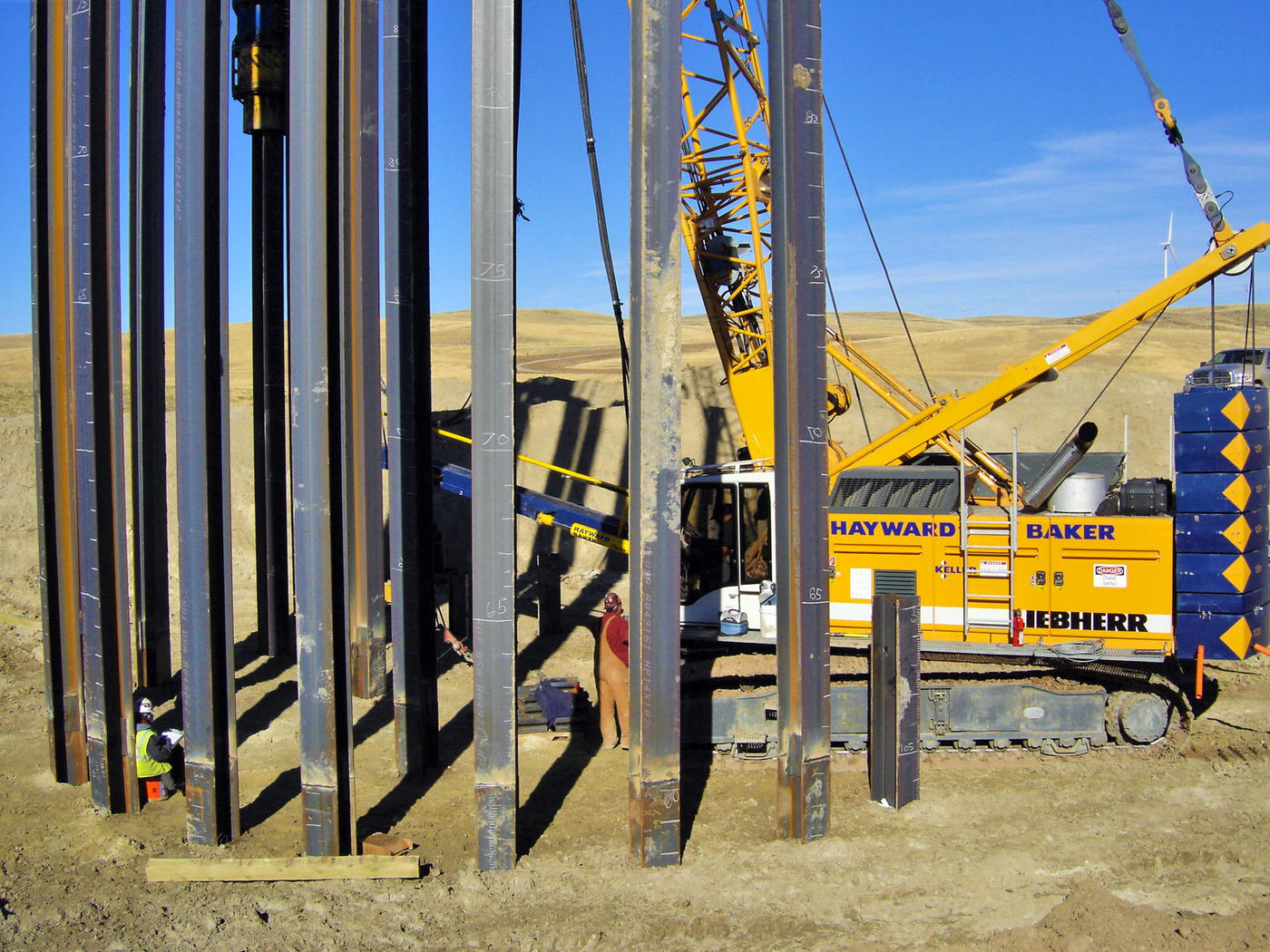

Previous experience of Keller’s ability to perform all three techniques resulted in a contract being issued for the owner-designated method to be performed as specified. Subsequently, Keller performed DDC to improve the bearing soils beneath 13 wind tower generators in areas where mine spoil depths ranged from 24 to 42 ft. Where mine spoil depths ranged from 50 to 70 ft, a total of 360 micropiles were installed at 15 locations. At 28 locations, Keller installed a total of nearly 500 driven H-piles into claystone bedrock where mine spoil ranged in depth between 70 and 100 ft.